I recently visited MIT’s Research Lab of Electronics (RLE) in Cambridge, Massachusetts. I heard there was a scientist there, Dr. Yoel Fink, who could make the fibers in our clothing see and hear. Dr. Fink, the director of RLE, said he had looked down at his clothes one day and wondered, “Why, when everything around us is advancing so rapidly, has clothing lingered behind?”

I recently visited MIT’s Research Lab of Electronics (RLE) in Cambridge, Massachusetts. I heard there was a scientist there, Dr. Yoel Fink, who could make the fibers in our clothing see and hear. Dr. Fink, the director of RLE, said he had looked down at his clothes one day and wondered, “Why, when everything around us is advancing so rapidly, has clothing lingered behind?”

It was a good question.

He then propped an iPad on his desk to show me some slides, starting with a picture of the Wright brothers during the first powered flight, in 1903 (that flight lasted 59 seconds). Dr. Fink explained that when planes took off the ground for good, about 15 years later, it was not because of an engine tweak, or re-shaped wing. It was because someone combined the might of steel with the light density of aluminum to make a high-strength, lightweight aluminum alloy.

Similarly, he explained, when computers became desk-size, all the while fast enough to do complicated calculations, it was not because an engineer had re-wired a coil or found a greater power source; it was because a method had been devised for making silicon (most of which is unrefined) highly pure. Pure silicon has properties that make it alone work beautifully in tiny, little semiconducting networks—the backbone of modern computers.

Similarly, he explained, when computers became desk-size, all the while fast enough to do complicated calculations, it was not because an engineer had re-wired a coil or found a greater power source; it was because a method had been devised for making silicon (most of which is unrefined) highly pure. Pure silicon has properties that make it alone work beautifully in tiny, little semiconducting networks—the backbone of modern computers.

In both cases—flight and the personal computer—a vision to create a life-changing technology was enabled by the development of a new material from an old one (or a couple old ones). Today, advances on both fronts continue; computers respond to voice recognition, and planes in Afghanistan are flown by droids in Colorado. Meanwhile, phones, cars, and other devices on which we rely are also becoming more functional. Why haven’t our clothes, the very product we can’t leave home without, gotten handier, too?

The answer, Dr. Fink explained, lies in the architecture of the common thread (or fiber) that makes up a shirt or a pair of jeans. Essentially, it is too simple—comprised of a single material, like cotton, and possessing a straightforward geometry. By comparison, the processors of a Macbook Air are made of multiple materials assembled together at a very small scale in an elegant form that permits them to perform advanced tasks, like communications, display and computation. Theoretically, if clothing were made of such complex fibers, it could do much more than keep you warm.

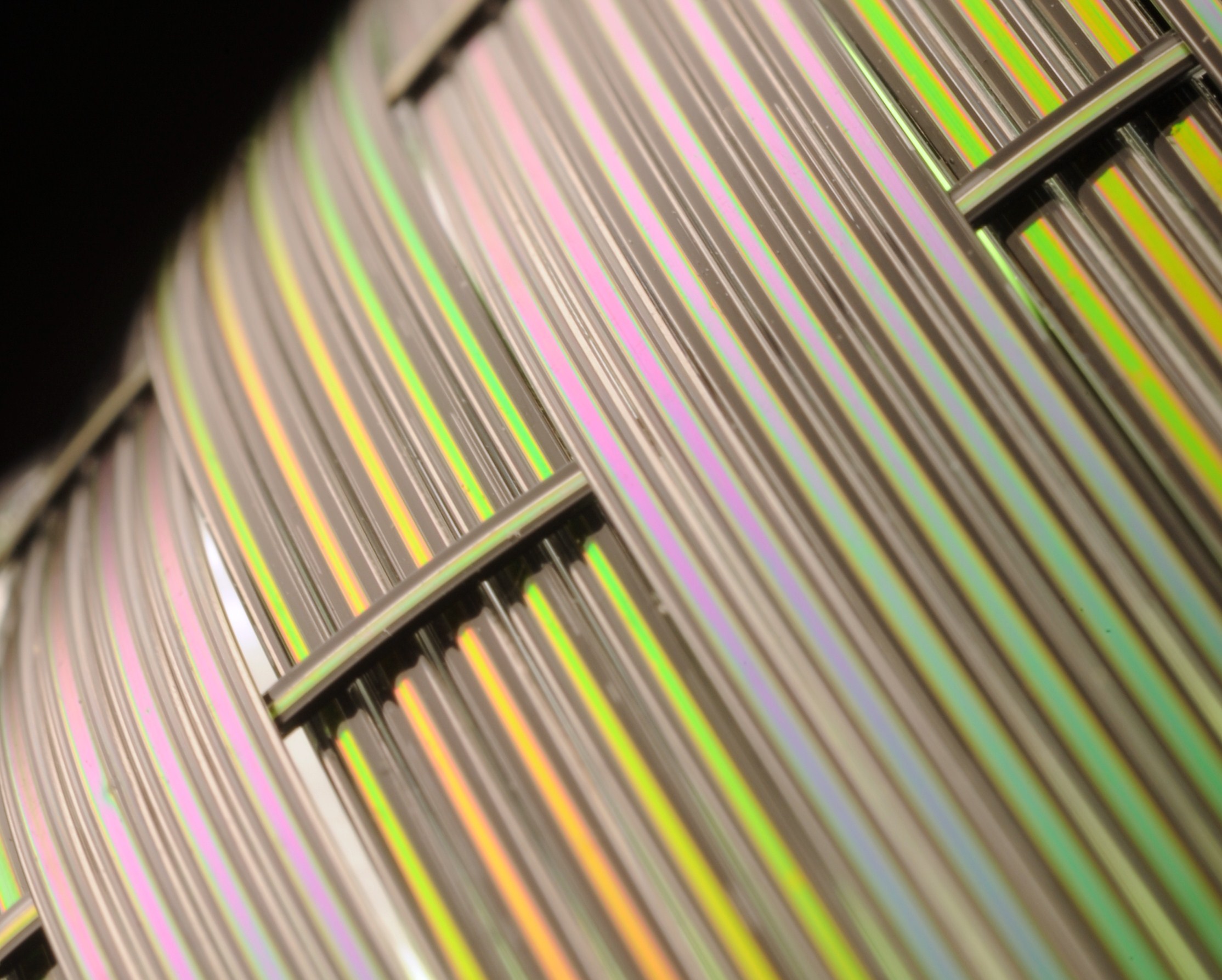

At the Research Lab of Electronics, Dr. Fink’s research team has been developing such highly functional fibers for nearly ten years. Through a process in which foot-long rods of metal wires are fused together and drawn into slender strands with elaborate cross sections, his team has developed multi-material fibers that can “see” by detecting light (much like optical devices) and “hear” by detecting different frequencies (similar to acoustic gadgets). These sophisticated strands can even direct the frequencies they detect thereby emitting sound, and reflect the light pixels they absorb, thus displaying color.

At the Research Lab of Electronics, Dr. Fink’s research team has been developing such highly functional fibers for nearly ten years. Through a process in which foot-long rods of metal wires are fused together and drawn into slender strands with elaborate cross sections, his team has developed multi-material fibers that can “see” by detecting light (much like optical devices) and “hear” by detecting different frequencies (similar to acoustic gadgets). These sophisticated strands can even direct the frequencies they detect thereby emitting sound, and reflect the light pixels they absorb, thus displaying color.

Some of them are already implemented in medical devices—tools that rely on thin, laser-like fiber strands to access hard to reach places in the body, while “observing” delicate tissue nearby and leaving it unharmed. Other applications for these revolutionary “threads” include health monitoring devices we could wear to detect slow but critical changes in our heartbeat, to fabrics soldiers could don—in conjunction with special glasses—to get continuous 360-degree views of the battlefield.

All Dr. Fink’s research started with one question: “How functional can this thing I’ve already got, a fiber, be?” It made me wonder in what other fields we could be posing this inquiry. For instance, how could we make ink smarter, or glue? I did a little digging to seek out ways other “common” materials are being advanced.

Smart Glass

Glass is already pretty intelligent; when covered in a special electrochromic coating, it can darken in response to jolts of electricity. Being darker changes the amount of visible light and heat (in the form of infrared radiation) it permits to pass. Electrochromic technology has been used in rearview mirrors to diminish the light reflected into a driver’s eyes and in tinted car windows to absorb heat, keeping vehicles cooler.

Recently, at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory, researchers discovered a way to make this glass coating even smarter. Previously, electrochromic windows could not control the amount of visible or infrared light they let pass; they could either block both regions of light or let both in. Now, researchers have designed a window coating that can choose the amount of infrared light to let into a building in order to optimize that building’s temperature. It could block heat in the summer, minimizing the need for air conditioning, and in the winter, it could let more in. The real trick is that this new coating (made by doping pre-existing electrochromic materials) works while remaining transparent (instead of tinting darker, as described above). Since treated windows remain clear, they don’t block visible light. Imagine keeping heat out of your house while letting sunshine stream through; this would cut down the need for air conditioning and lighting. According to studies conducted at the National Renewable Energy Laboratory, this new smart window coating could offset the use of air conditioning by up to 49 percent and lighting by up to 51 percent.

Watching paint dry on your house is no picnic. But what about watching that paint generate electricity, and maybe even enough to power your household appliances? Last year, researchers at Notre Dame’s Center for Nano Science and Technology made great strides towards this idea. They put tiny power-producing particles, called quantum dots, into a spreadable compound. The compound can be applied without special equipment. When exposed to light from the sun, it creates electricity.

So far, the paint’s best light-to-energy conversion efficiency is only 1 percent (compared to the 10 to 15 percent efficiency of solar cells), but it is easy and cheap to make, so it has real potential if its efficiency can be improved.

Smart Ketchup

Heinz may say the best way to coax ketchup from a bottle is to apply a firm tap to the bottle’s neck. But at MIT this spring, engineers created a ketchup bottle that doesn’t require a tap, shake or probing by knife to keep even the last bits of condiment flowing. They did this by applying a nontoxic, FDA-approved coating made from food materials to the bottle’s interior. Voila! No more tasty ketchup traces left behind… (MIT: can you please apply this super-slick coating to my mustard and shampoo bottles as well?)

Concepts like those described above don’t always become real-life products easily; resources are limited, and scientists must constantly balance risk with potential payout. “Without actually going into large-scale production, it’s impossible to answer definitively the true impact of any product,” said Dr. Bruce van Dover, Director of Graduate Studies at Cornell University’s Department of Material Science and Engineering, “but that doesn’t mean we scientists or engineers can’t ever make estimates.”

He believes one way for innovations to succeed is for scientists to continue reevaluating new roles for old materials. “Whether any particular scientific advances will result in technologies that change our lives for the better is not certain; experience has taught us that it is impossible to predict the long-term winners and losers no matter how clever we try to be. That is why it is essential to conduct basic research, developing a deep understanding of the fundamentals and formulating from them new ideas and concepts.”

_________________

Meagan is a Boston-based science writer who currently works as a Senior Writer at AIR Worldwide, the best catastrophe modeling firm around; AIR has no interest whatever in sensing fibers. She’s half of a blog, The Boston Project. In her free time, she enjoys long runs to techno beats and golfing with her better half, Jeremy.

Photo credits:

Both fiber photos used with the kind permission of Research Laboratory of Electronics at MIT / Greg Hren Photography

Wilbur Wright in 1903 at Kitty Hawk, North Carolina; Wikimedia commons.

Paint can by DBduo Photography

One thought on “Guest Post: Reinventing the Wheel”

Comments are closed.